RE-NUT Inc. (AG)

Rosenbergstrasse 8

9000 St.Gallen

Switzerland

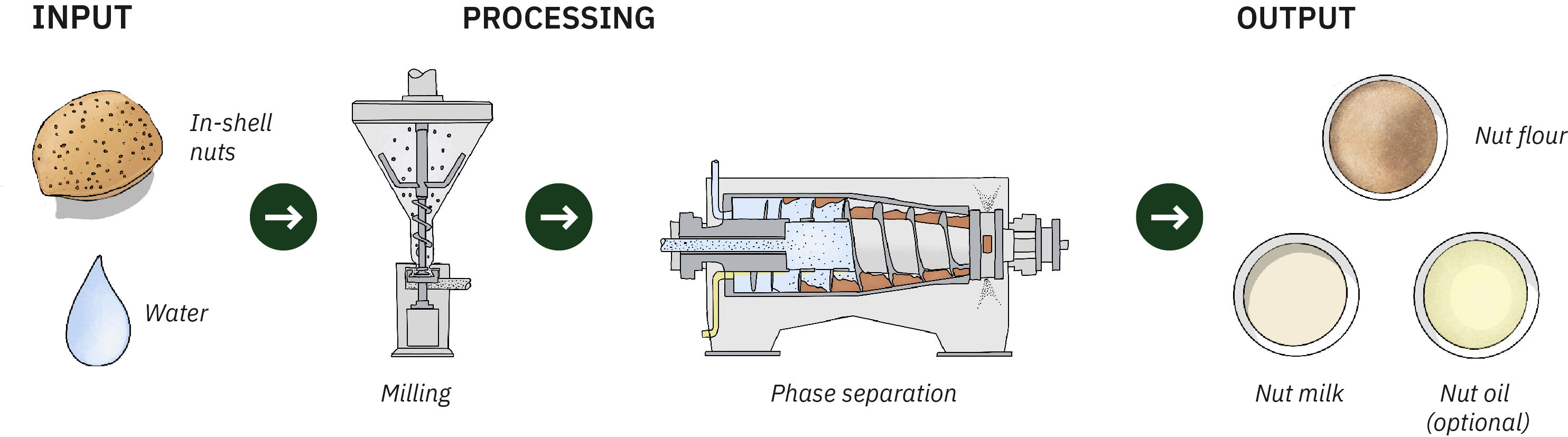

The new RE-NUT® method processes the nuts «in-shell», which means without shelling them. This doubles the yield of nut flour, paste and milks. Moreover this leaves in all the nutshells’ valuable fiber and antioxidants. This patent-protected technology is now ready to be licensed by nut processors and food companies.

More about Licensing

More about Licensing

In-shell nuts

In-shell nuts

Water

Water

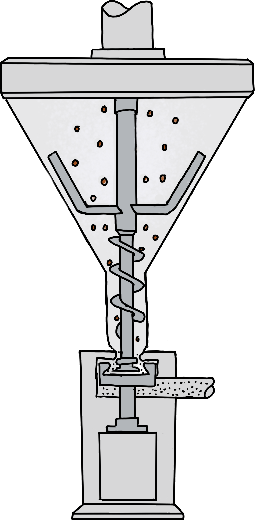

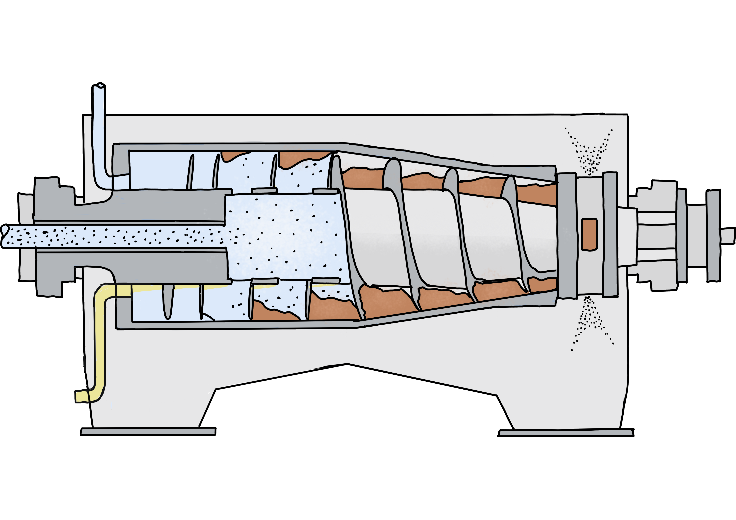

Wet-milling of in-shell nuts to achieve the targeted particle size.

Phase separation of the slurry via decanter.

Solids

Solids

Oil

Oil

Milk

Milk

Three valuable extracts obtained from the continuously running RE-NUT® process: nut solids, nut milk, (optionally nut oil). Waste/ side products? Zero.

More about Technology

They are delicious and packed with unsaturated fats, fibers, protein and vitamins, which makes nuts an important food ingredient: nut butter and paste, flour or fillings deliver flavor, texture and nutritional benefits to chocolates, spreads, bakery products, yoghurts, cream cheese, ice cream or nut milks. However, an important part of the whole nut has been neglected so far: the nutshells.

The shell accounts for about the same mass as the kernel and is full of nutritional value. Today nutshells are considered as waste or low-value by-products. This is exactly where enormous, untapped potential lies.

Nut cultivation requires vast amounts of water and farmland. The use of these vital and increasingly scarce resources per pound of nut yield is massively reduced by using not only the kernels but the whole, unshelled nuts.

Considering the global nut production of 55 Mio. tons (2021), millions of tons of nutshells full of fiber and antioxidants are burned or used as livestock feed and bedding every year. Processing unshelled nuts eliminates part of this immense food loss and boosts the sustainability footprint of the entire nut industry.

Nutshells consist primarily of dietary fibers and contain a lot of healthy antioxidants. While fibers are an important part of a healthy nutrition, the antioxidant effects of the nut shells’ phenolic compounds help to neutralize free radicals in the human body. By processing the nuts with their shells, all these benefits are added to the resulting nut ingredients, revealing the nuts’ full potential.

On average, the shell of a nut weighs about the same as the kernel. Therefore, processing the nuts with their shells results in double the amount of nut solids, a key ingredient for the food industry. The resulting amount of ready-to-drink nut milk can also be massively increased by adding water in the process.

Shelling the harvested nuts to obtain the kernels is expensive. Directly processing in-shell nuts makes this process step obsolete and significantly reduces manufacturing costs of nut products. In addition, as long as the kernel remains in nature’s best packaging (the nutshell), less oxidation results in a longer shelf life.

The in-shell nut solids are the perfect, 100% natural filler that allows sugar reduction in confectionary, chocolate spreads, cookies, etc.

We RE-define the value of culinary nuts by unlocking their full potential from field to delight. We’re thrilled to make significant contributions in four key areas.

Provision of valuable fibers, vitamins and antioxidants to the growing world population.

Healthy indulgence through sugar replacement in high sugar foods.

More efficient use of water and farmland resources in nut cultivation.

Avoidance of food loss and waste.

Unshelled whole nuts are our raw material, getting more out of them is our expertise. Instead of separating the shell from the kernel, our RE-NUT® method boosts the yield of nuts by processing them with their outer hard shells. We provide licenses and all the required know-how on our patented manufacturing process to our clients. This enables nut processors, nut ingredient providers and food companies to produce nut flour, paste or butter which not only contain the known ingredients from the kernels, but all the valuable fiber and antioxidants of the nutshells.

More about LicensingDuring a visit to hazelnut plantations in Turkey in 2016, Roland Laux and Tilo Hühn came up with the idea of processing hazelnuts with their outer hard shells. This idea, which at first glance seemed as simple as it was crazy, sparked their motivation to learn as much as possible about the potential of nuts with shells.

Over the past 20 years, we have observed that through large scale manufacturing methods, much of the original goodness of raw materials like fruits, herbs, cocoa and coffee beans or nuts is lost through heating, drying and oxidation.

Precisely because of this, we have been fascinated by the idea of bringing ‘more of the goodness’ of raw materials into finished food products. More flavors, more vitamins, more fiber, more polyphenols.

This nut adventure continues seamlessly.

It all began in 2006 with an idea from Roland and Tilo on their visit to a chocolate factory in Venezuela: instead of dry-processing cocoa beans at high pressure and temperatures, they had the idea of wet-milling unroasted beans with cold water to get a slurry, which then is separated into the different extracts cocoa butter, solids and liquids by phase separation technology. This way, all the wonderful, complex aroma of cocoa beans can be captured in the final chocolate. Roland Laux and the Zurich University of Applied Sciences (ZHAW) sold the patent in 2014 to Dieter Meier, who now industrially produces “Oro de Cacao” chocolate in Switzerland. Further implementations of this technological principle followed for cold-brew coffee and whole coffee cherries (RE-COFFEE) as well as spices and herbs.

The RE-NUT® team combines process engineering skills and scientific expertise with many years of international business experience.

Roland Laux

Roland Laux Prof. Dr. Tilo Hühn

Prof. Dr. Tilo Hühn Louis Siegrist

Louis Siegrist Christian Zimmermann

Christian Zimmermann Gisbel Biland

Gisbel Biland Timothy Smith

Timothy Smith Scott Hanneson

Scott Hanneson Claudio Garcia

Claudio Garcia Shahrzad Tafazoli, Ph.D.

Shahrzad Tafazoli, Ph.D. Matt Suter

Matt Suter Prof. Dr. Hans Verhagen

Prof. Dr. Hans VerhagenReady for a new journey? Become a part of our dynamic and growing start-up. Contribute actively to our success at RE-NUT. Let’s grow together.

View Open Positions

CONTACT US

CONTACT US

*required field

Your data will be processed by RE-NUT AG and its associated companies in accordance with our disclaimer.

Rosenbergstrasse 8

9000 St.Gallen

Switzerland

info@re-nut.com

+41 (0)71 228 55 44